The five-layer co-extrusion pipe production line has become the preferred choice in the industry due to its strong technical capabilities

Material handling system: It includes vacuum feeders and drying hoppers (4 units), responsible for precisely conveying and drying raw materials such as PE, EVOH, and adhesives, ensuring the purity and stability of the materials, and laying the foundation for subsequent extrusion.

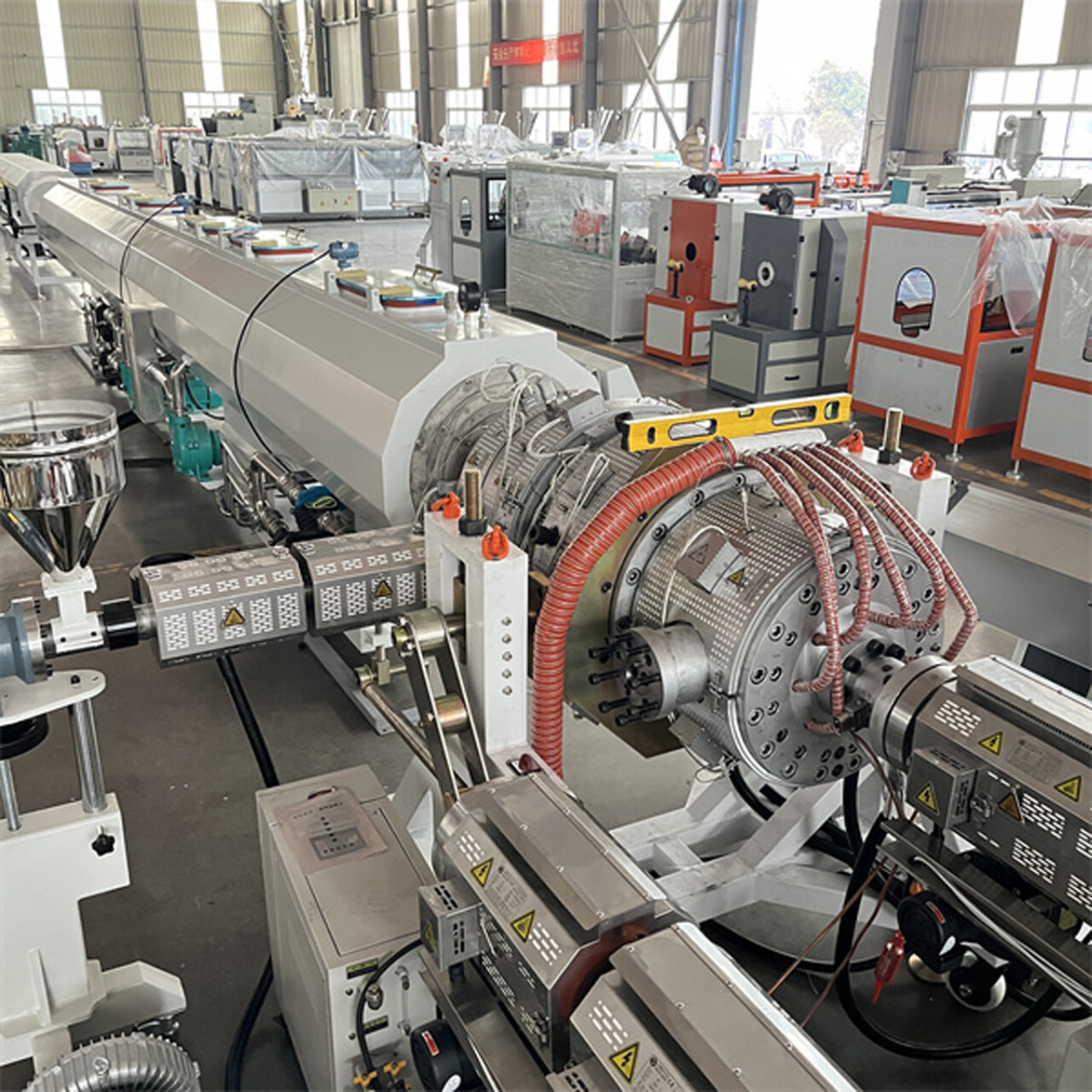

Extrusion unit: Composed of multiple single-screw extruders of different models, it achieves independent feeding in a five-layer structure.

Forming and shaping system: The mold (including die, mandrel, etc.) fuses five layers of materials to form the initial shape of the pipe. The 9-meter vacuum box rapidly sizing through negative pressure, and the 9-meter spray box further cools and solidifies to ensure the dimensional accuracy of the pipe (such as the cutting accuracy without chips ≤5mm).

Post-processing system: The three-jaw traction machine (driven by servo motor) stably controls the production line speed (0.3-8m/min), the chipless cutting machine precisely cuts, the single-station winding machine neatly collects materials, and is equipped with a hot melt printer (with a meter accuracy of ±0.3%) to achieve clear marking. The entire process is fully automated in a closed loop.

Recommended products