Double Wall Corrugated Pipe Production Line is a type of manufacturing equipment used to produce double wall corrugated pipes. These pipes are commonly used in various applications such as drainage systems, sewage systems, cable protection, and telecommunications.The machine typically consists of several components and stages that work together to produce the double wall corrugated pipes. Here is a general overview of the process:

Extrusion System: The extrusion system is responsible for melting and extruding the raw material, usually high-density polyethylene (HDPE), into a continuous pipe. The HDPE resin is fed into the extruder, where it is heated and melted before being forced through a die. The die determines the shape and size of the pipe.

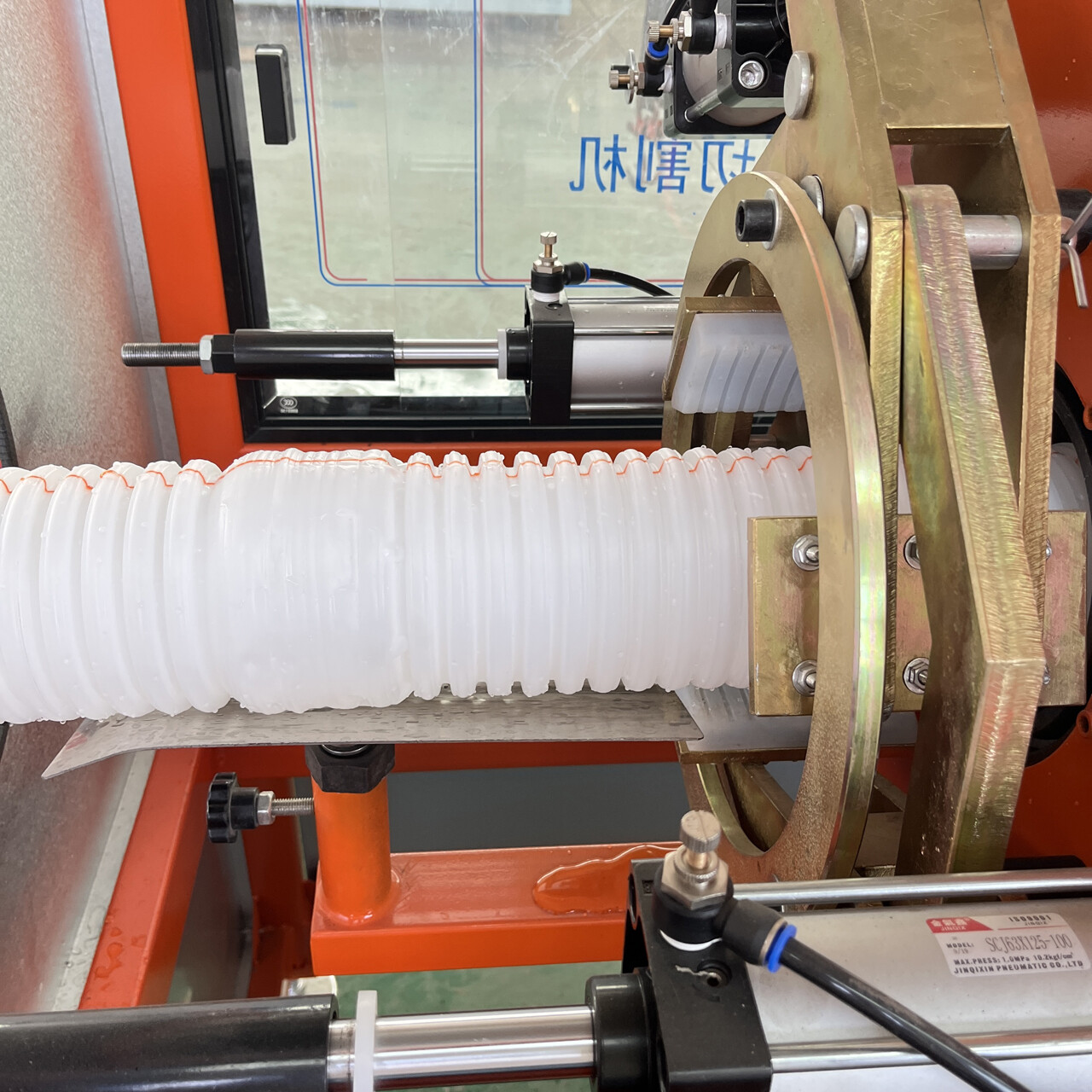

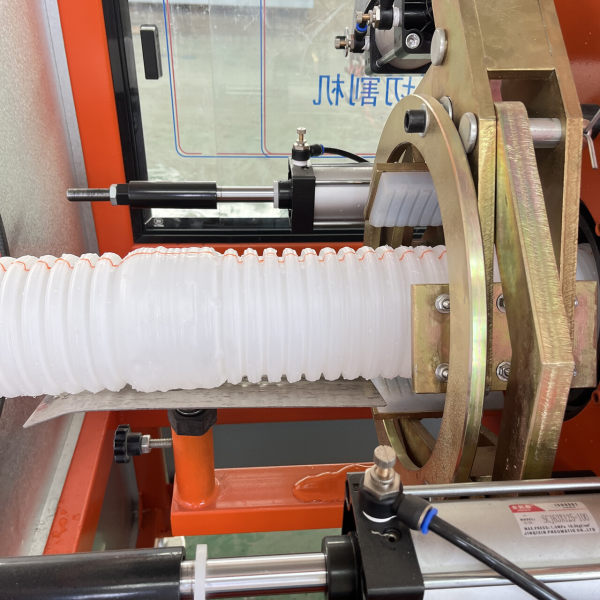

Corrugation System: Once the molten HDPE passes through the die, it enters the corrugation system. This system consists of a set of corrugating rolls or molds that impart the characteristic corrugated pattern onto the pipe. The rolls or molds shape the pipe while it is still in a semi-molten state.

Cooling and Forming: After the corrugation process, the pipe enters a cooling section to solidify the material. Cooling can be achieved through various methods, such as air cooling or water cooling.

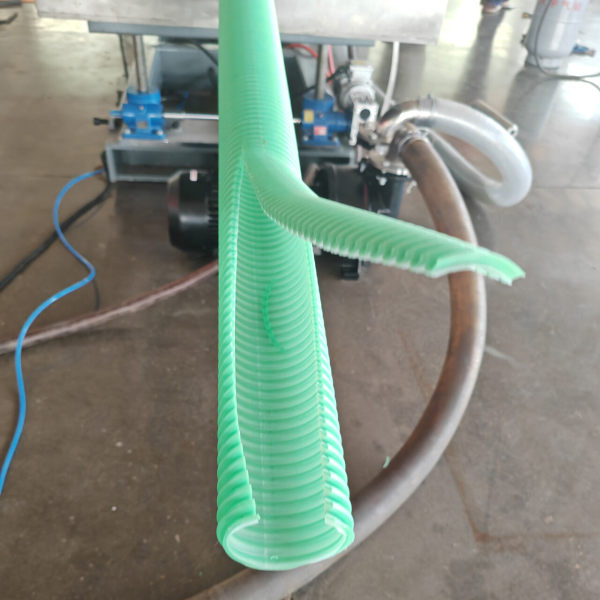

Once the pipe is cooled and solidified, it is formed into its final shape and cut to the desired length. The forming process may involve additional molds or shaping equipment to achieve the required dimensions.

Double Wall Construction: In this stage, a second layer of HDPE is added to create the double wall structure. The second layer is typically extruded onto the outer surface of the corrugated pipe.

The two layers are then bonded together to form a strong and durable double wall pipe.

Project evaluation

1.1 Basic Infrastructure (Provided by customer)

a. Electricity network: can adjustable according to your local voltage standard.

b. Wire/cables: wires/cables from customer’s general control cabinet to the main control cabinet for PVC corrugated pipe production line; all electrical cable from the main control cabinet to each machine.

c. Water supply: main water pipe line supply and water pipes to machines

d. Compressed air supply: necessary compressed air for mould, forming machine, winder

e: lubrication oil: for reducer gearbox

1.2 Energy consumption:

a. Electricity requirement

Total Install power: 70KW.

Actual power consumption percentage: 80% of total power

b. Labor requirement

Max. Qty. of labors: 1 person

c: compressed air requirement: 0.4Mpa-0.8Mpa

Are you a factory or a trading company?

A: We are our own factory, covering an area of more than 20,000 square meters. The main production of plastic pipe, profile, plate machine and recycling machine.

How about quality control in your company?

A: We pay great attention to quality control from start to finish and have a 12-month quality assurance period. We test the performance of the machine before each delivery. Provide process development, service guidance, turnkey engineering. Third party inspection is welcome.

What are your main products?

A: Our main production lines as below: A: Our main production lines as below:

1. PVC PE PP PA single/double corrugated pipe machine

2. PP PE PVC PC pipe machine and metal corrugated pipe machine

3. PVC PP PE WPC PS TPE profile machine

4. PVC WPC foam board machine and PP hollow sheet machine.

Can I make customer brand names?

A: Yes, we welcome Oems.

Where is your loading port?

A: Qingdao, China.