MPP PP Pipe Production Line introduction:

The MPP cable sleeve (pipe jacking) production line developed by Qingdao Cuishi Plastic Machinery Manufacturing Co., Ltd. has the characteristics of unique structure, high degree of automation, convenient operation, stable and reliable continuous production. The pipes produced by this production line have good rigidity, strength, flexibility, creep resistance, environmental stress cracking resistance and good hot melt performance, and have become the first choice for urban cable sheathed pipes.

This series of production line mainly includes high-speed single screw extruder, pipe mold, vacuum sizing water tank, spray cooling water tank, tractor, chip free cutting machine and discharge rack.

Extruder: high speed and high efficiency single screw extruder, screw with barrier and mixing head integrated mixing components, equipped with low noise fan, ceramic heating ring, high speed hard gear reducer, automatic vacuum feeding, plasticizing and mixing effect is good, to ensure high speed and high performance extrusion.

Marking line: The pipe marking line is extruded by a single screw extruder SJ-30/25 through a composite die.

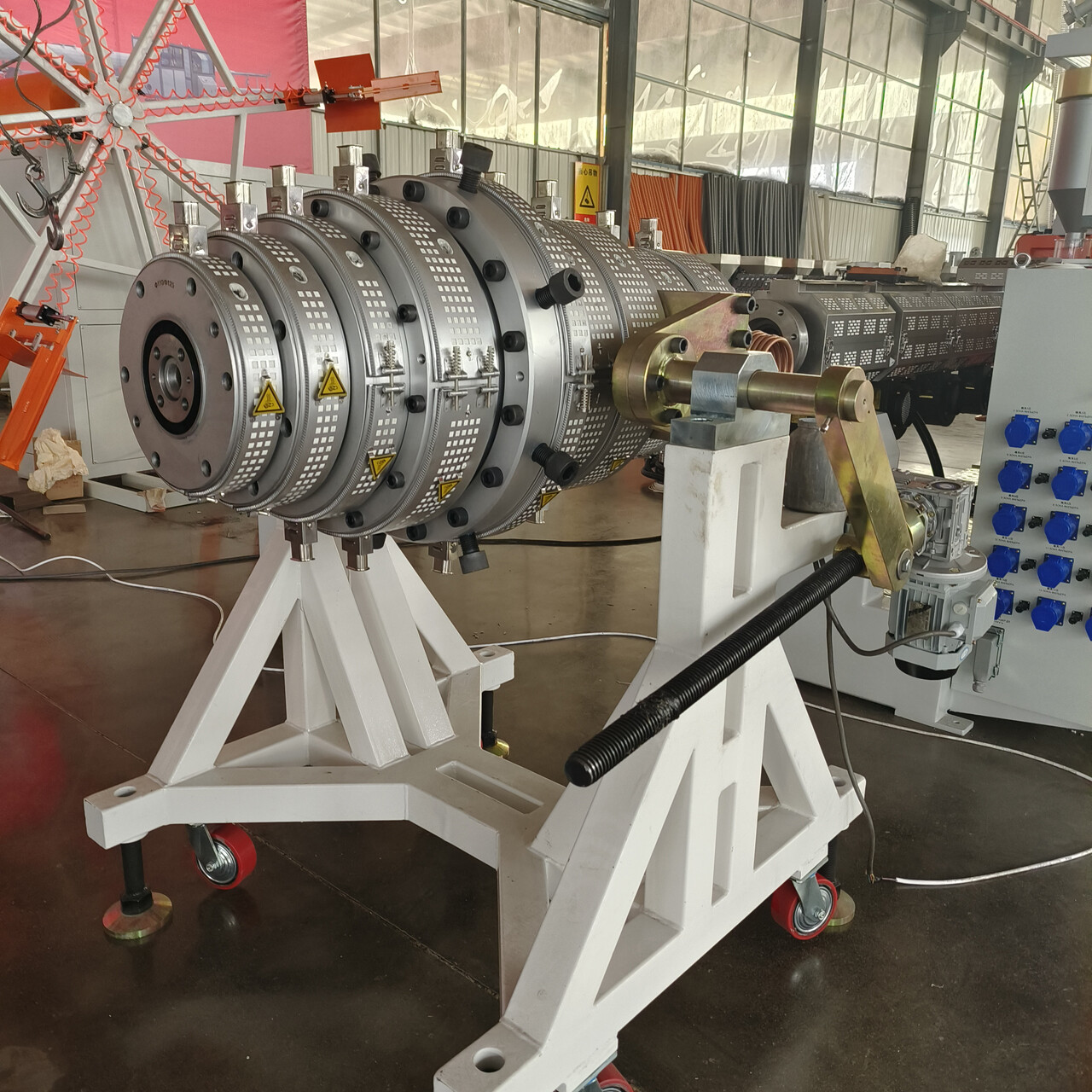

Extrusion mold: The mold material is high quality 40Cr, the selection of internationally advanced spiral or blue die technology, stable and reliable extrusion, the use of water film lubrication and water ring cooling, to meet the requirements of MPP materials, to ensure the high-speed production of thick wall pipe diameter and roundness stability.

Vacuum sizing water tank: The box adopts 304 stainless steel plate, advanced water circulation, high pressure cooling system, vacuum adjustment device and accurate water temperature and level automatic control system. The precise tin bronze sizing sleeve has the characteristics of fast pipe cooling and fast setting. Up, down, left, and right can be adjusted in three dimensions to provide cooling configurations of different lengths and quantities depending on the size and speed of the pipe being produced.

Spray cooling water tank: The box is made of 304 stainless steel, and the sealing ring is transparent soft PVC. Stainless steel float to adjust water level, electric control water temperature regulation. The nozzle material is engineering plastic ABS. The frame can be adjusted up and down, and the box is provided with a wheel support mechanism.

Traction machine: according to the different pipe diameter and pipe wall thickness respectively equipped with double track, three claws, four claws, five claws and six claws and other traction machines. The machine adopts frequency conversion speed regulation mode. Each traction frame adopts chain splitting to ensure the same traction speed, pneumatic and mechanical joint clamping, bearing with seat aligning structure, which can effectively reduce the installation error.

Cutting machine: no chip automatic cutting saw, cutting section is smooth and flat, the use of frequency control synchronous drive, high precision, low noise. Large diameter pipe using automatic planetary cutting machine, synchronous with the production line, saw blade position and cutting depth can be flexibly adjusted to ensure the reliability of the cutting saw.

Production line control system: Delta frequency conversion control system can be selected, intelligent control. General control using Siemens electrical parts, Japan Omron temperature control meter, control is simple and easy to operate.

MPP cable sleeve (pipe jacking) production line introduction:

The MPP cable sleeve (pipe jacking) production line developed by Qingdao Cui Plastic Machinery Manufacturing Co., Ltd. has the characteristics of unique structure, high degree of automation, convenient operation, stable and reliable continuous production. The pipes produced by this production line have good rigidity, strength, flexibility, creep resistance, environmental stress cracking resistance and good hot melt performance, and have become the first choice for urban cable sheathed pipes.

This series of production line mainly includes high-speed single screw extruder, pipe mold, vacuum sizing water tank, spray cooling water tank, tractor, chip free cutting machine and discharge rack.

Extruder: high speed and high efficiency single screw extruder, screw with barrier and mixing head integrated mixing components, equipped with low noise fan, ceramic heating ring, high speed hard gear reducer, automatic vacuum feeding, plasticizing and mixing effect is good, to ensure high speed and high performance extrusion.

Marking line: The pipe marking line is extruded by a single screw extruder SJ-30/25 through a composite die.

Extrusion mold: The mold material is high quality 40Cr, the selection of internationally advanced spiral or blue die technology, stable and reliable extrusion, the use of water film lubrication and water ring cooling, to meet the requirements of MPP materials, to ensure the high-speed production of thick wall pipe diameter and roundness stability.

Vacuum sizing water tank: The box adopts 304 stainless steel plate, advanced water circulation, high pressure cooling system, vacuum adjustment device and accurate water temperature and level automatic control system. The precise tin bronze sizing sleeve has the characteristics of fast pipe cooling and fast setting. Up, down, left, and right can be adjusted in three dimensions to provide cooling configurations of different lengths and quantities depending on the size and speed of the pipe being produced.

Spray cooling water tank: The box is made of 304 stainless steel, and the sealing ring is transparent soft PVC. Stainless steel float to adjust water level, electric control water temperature regulation. The nozzle material is engineering plastic ABS. The frame can be adjusted up and down, and the box is provided with a wheel support mechanism.

Traction machine: according to the different pipe diameter and pipe wall thickness respectively equipped with double track, three claws, four claws, five claws and six claws and other traction machines. The machine adopts frequency conversion speed regulation mode. Each traction frame adopts chain splitting to ensure the same traction speed, pneumatic and mechanical joint clamping, bearing with seat aligning structure, which can effectively reduce the installation error.

Cutting machine: no chip automatic cutting saw, cutting section is smooth and flat, the use of frequency control synchronous drive, high precision, low noise. Large diameter pipe using automatic planetary cutting machine, synchronous with the production line, saw blade position and cutting depth can be flexibly adjusted to ensure the reliability of the cutting saw.

Production line control system: Delta frequency conversion control system can be selected, intelligent control. General control using Siemens electrical parts, Japan Omron temperature control meter, control is simple and easy to operate.

The MPP cable sleeve (pipe jacking) production line developed by Qingdao Cuishi Plastic Machinery Manufacturing Co., Ltd. has the characteristics of unique structure, high degree of automation, convenient operation, stable and reliable continuous production. The pipes produced by this production line have good rigidity, strength, flexibility, creep resistance, environmental stress cracking resistance and good hot melt performance, and have become the first choice for urban cable sheathed pipes.

This series of production line mainly includes high-speed single screw extruder, pipe mold, vacuum sizing water tank, spray cooling water tank, tractor, chip free cutting machine and discharge rack.

Are you a factory or a trading company?

A: We are our own factory, covering an area of more than 20,000 square meters. The main production of plastic pipe, profile, plate machine and recycling machine.

How about quality control in your company?

A: We pay great attention to quality control from start to finish and have a 12-month quality assurance period. We test the performance of the machine before each delivery. Provide process development, service guidance, turnkey engineering. Third party inspection is welcome.

What are your main products?

A: Our main production lines as below: A: Our main production lines as below:

1. PVC PE PP PA single/double corrugated pipe machine

2. PP PE PVC PC pipe machine and metal corrugated pipe machine

3. PVC PP PE WPC PS TPE profile machine

4. PVC WPC foam board machine and PP hollow sheet machine.

Can I make customer brand names?

A: Yes, we welcome Oems.

Where is your loading port?

A: Qingdao, China.