Plastic Extrusion Mould

Plastic Pipe Extrusion mold is a kind of molding mold, but his way of discharging is to achieve through the action of extrusion.It is widely used in aluminum shaped structure and also in plastic parts.In the front end of the extruder, used for making pipe, or profile. In short, the mold is used to shape the tool, this tool is composed of various parts, different mold is composed of different parts, it mainly through the formation of material physical state change to achieve the shape of the object processing.

The mould is the main processing tool for manufacturing parts in industrial departments such as machinery manufacturing, radio instrument, motor and electric appliance.The quality of die directly affects the quality of pressure processing technology, the precision output of products and production cost. Besides rational structure design and machining accuracy, the quality and service life of molds are mainly affected by mold materials and heat treatment.

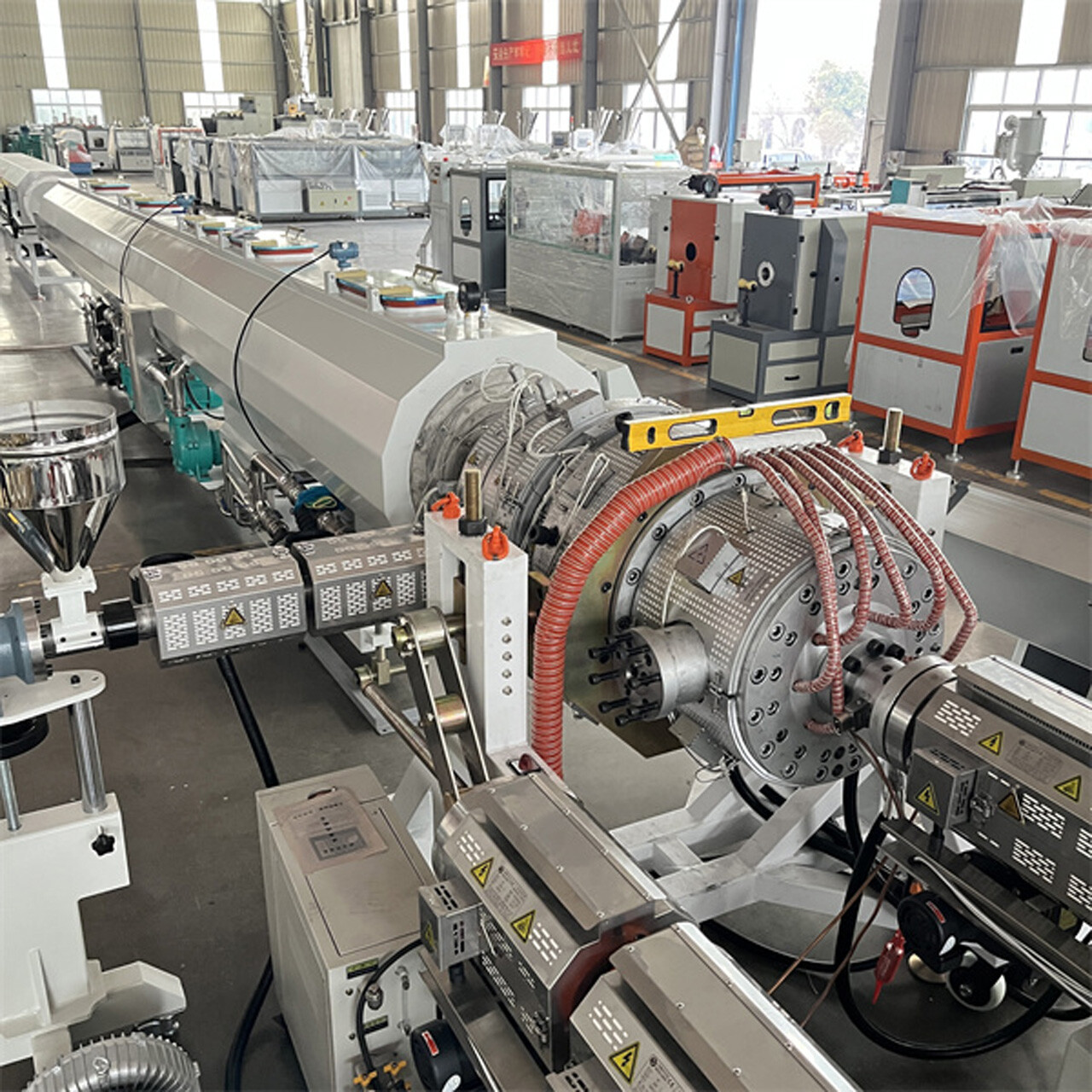

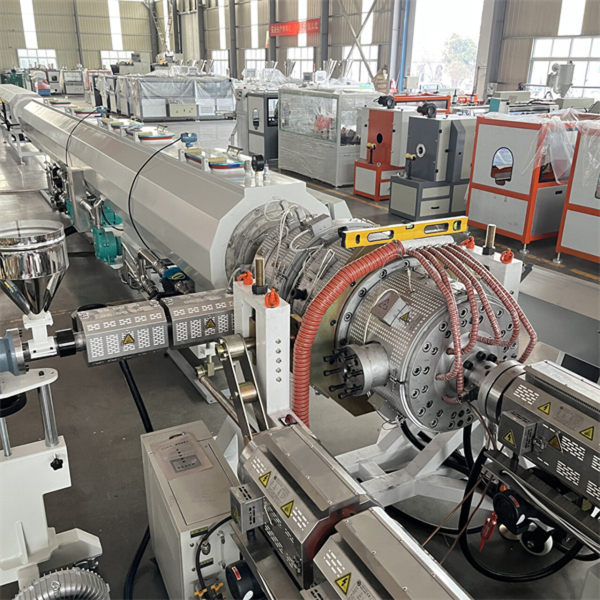

Plastic extrusion pipe molds are essential tools in the plastic processing industry, primarily used for manufacturing plastic pipes with various diameters and wall thicknesses.

These molds generally consist of several key components. The die head is the core part, which determines the outer diameter and shape of the pipe. It precisely controls the flow of molten plastic to ensure a uniform and smooth outer surface of the pipe. The sizing sleeve plays a crucial role in sizing and cooling the extruded pipe, helping to maintain its dimensional accuracy and surface quality. The core rod is used to form the inner diameter of the pipe and cooperates with the die head to control the wall thickness of the pipe.

Plastic extrusion pipe molds offer several advantages. They enable high-efficiency and continuous production, significantly increasing production capacity. They also ensure high precision in pipe dimensions, meeting strict quality standards. Moreover, with the ability to customize different shapes and sizes, they can meet a wide range of application requirements in various fields such as construction, water supply and drainage, and telecommunications.

In conclusion, plastic extrusion pipe molds are of great significance in the plastic pipe manufacturing process, contributing to the production of high-quality plastic pipes and promoting the development of related industries.

Are you a factory or a trading company?

A: We are our own factory, covering an area of more than 20,000 square meters. The main production of plastic pipe, profile, plate machine and recycling machine.

How about quality control in your company?

A: We pay great attention to quality control from start to finish and have a 12-month quality assurance period. We test the performance of the machine before each delivery. Provide process development, service guidance, turnkey engineering. Third party inspection is welcome.

What are your main products?

A: Our main production lines as below: A: Our main production lines as below:

1. PVC PE PP PA single/double corrugated pipe machine

2. PP PE PVC PC pipe machine and metal corrugated pipe machine

3. PVC PP PE WPC PS TPE profile machine

4. PVC WPC foam board machine and PP hollow sheet machine.

Can I make customer brand names?

A: Yes, we welcome Oems.

Where is your loading port?

A: Qingdao, China.